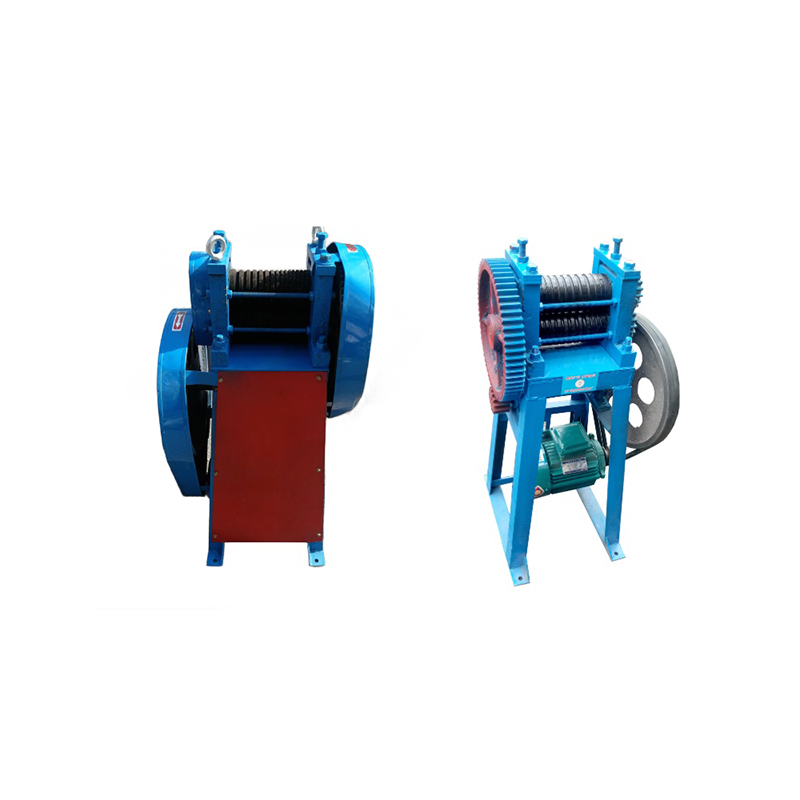

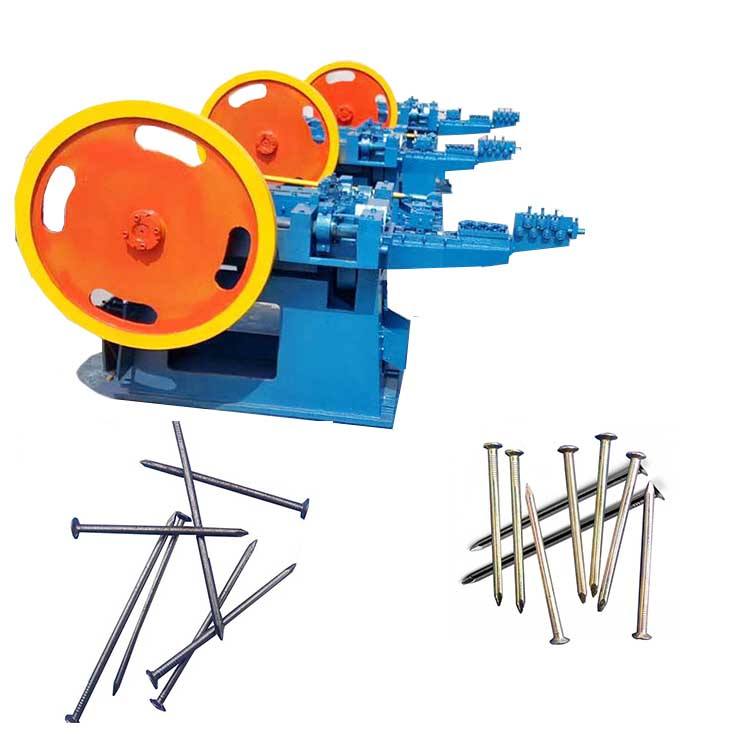

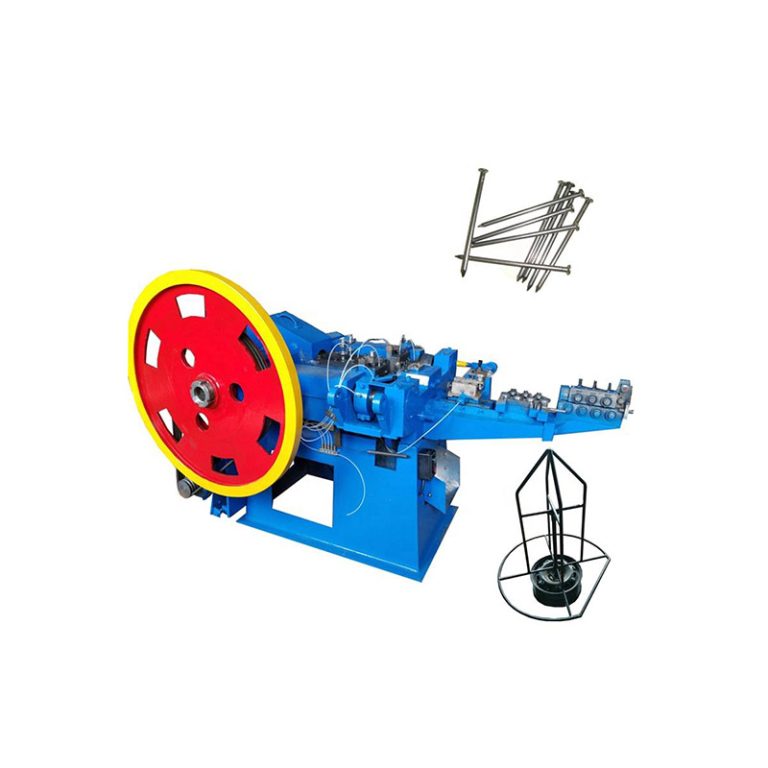

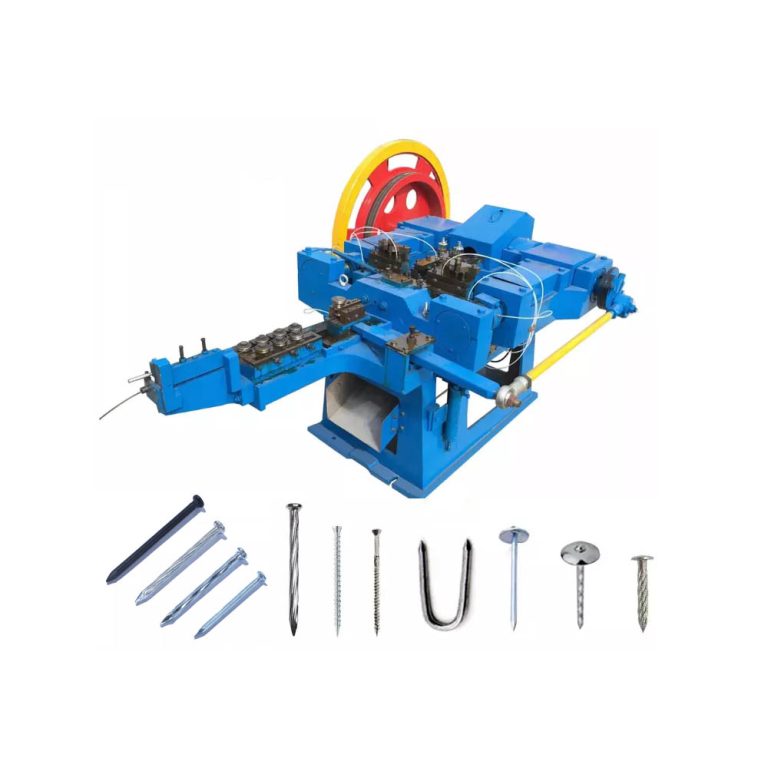

Wire pointing machine is an essential piece of equipment used in the wire drawing process. Wire drawing is a metalworking process used to reduce the diameter of a wire by pulling it through a series of drawing dies. The wire pointing machine is specifically designed to create a pointed end on the wire, which is necessary for threading the wire through the drawing dies.

The wire roll tipping machine is a mechanical equipment for metal wire drawing machines and cold-drawn production equipment. The end of the raw material must be rolled by the tipping machine and passed through the drawing die hole before the material can be drawn.

How to operate wire pointing machine

- Before working, check whether the material support is stable, whether the machine switch is effective, and whether the gear guard is firm.

- Before starting up, clean up the tools and sundries on the work site and the machine tool.

- When adjusting the roll gap, the gap pressure should not be too large to prevent the material from rolling cracks. When rolling the tip, apply pressure gradually instead of rolling it all at once.

- Check whether the actual size, geometry and hardness of the wool meet the requirements. It is forbidden to process unannealed bar materials to prevent crushing rolls or breaking out of pieces to hurt people.

- When the operator throws down the material, pay attention to the safety of the people around. When cutting the bundled wire, prevent the bar from rolling or the wire ejected and hurt people. The bundled wire should be cleaned up in time.

- When feeding and rolling, you must hold the rod tightly to prevent the rod from sliding or tilting. When processing materials with a diameter of more than 18 mm, two people must work together and pay attention to coordination.

Overall, Wire pointing machine is a vital tool in the wire production industry, enhancing both productivity and quality in wire manufacturing processes.