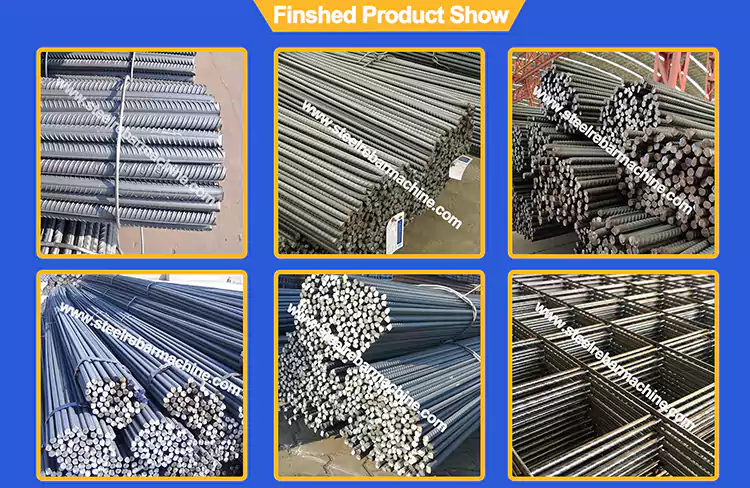

Waste rebar straightening machine is a specialized device designed to straighten bent or deformed steel reinforcing bars (rebar) that are typically used in concrete construction. These machines are particularly useful in recycling and reusing rebars that would otherwise be considered waste, thus promoting sustainability in construction projects.

The scrap rebar straightening machine is perfect for independent use, this machine is remarkably small, ensuring hassle-free maneuverability by a single operator. Its efficiency surpasses manual straightening methods by over 20 times, providing a modern alternative to traditional machinery.

The main feature of waste rebar straightening machine

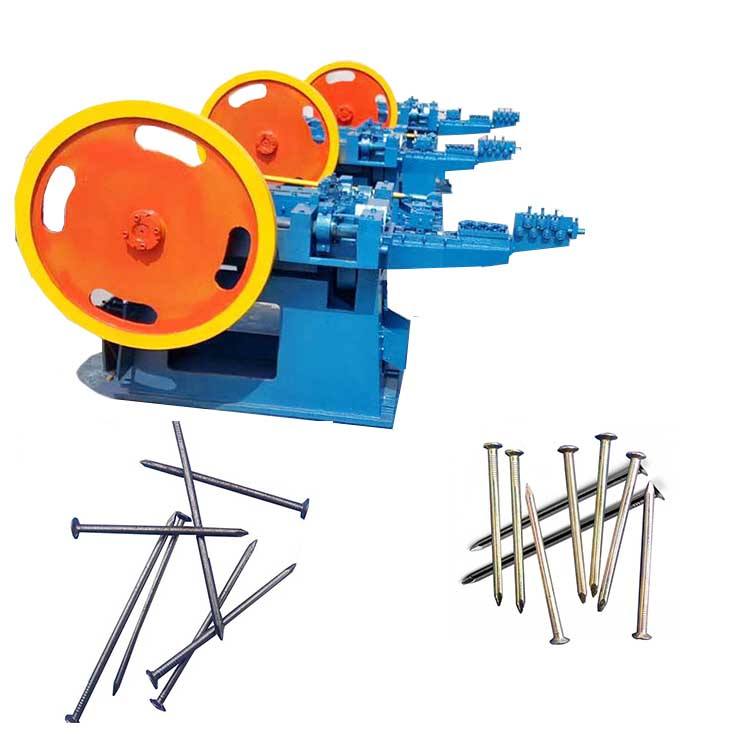

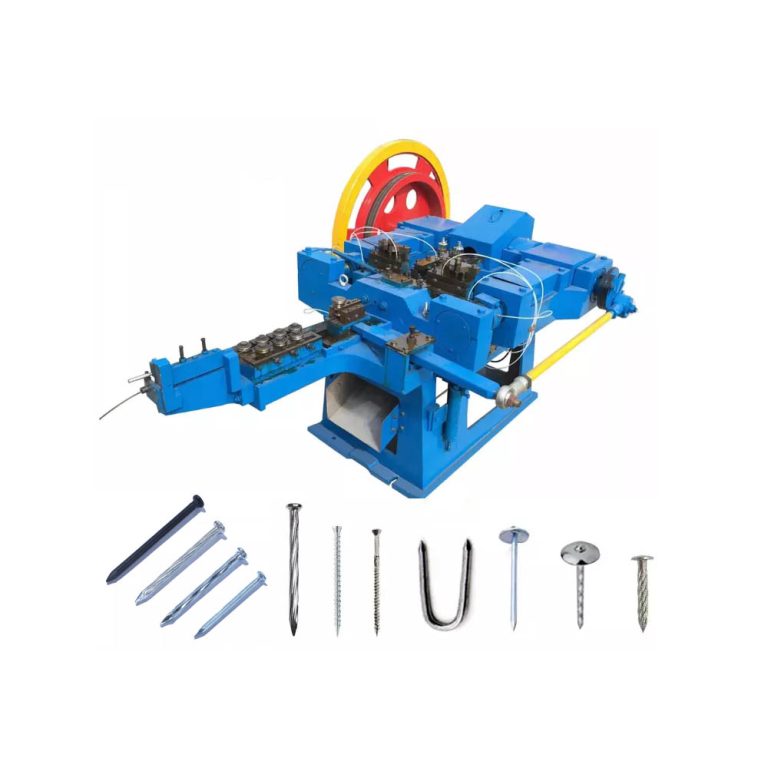

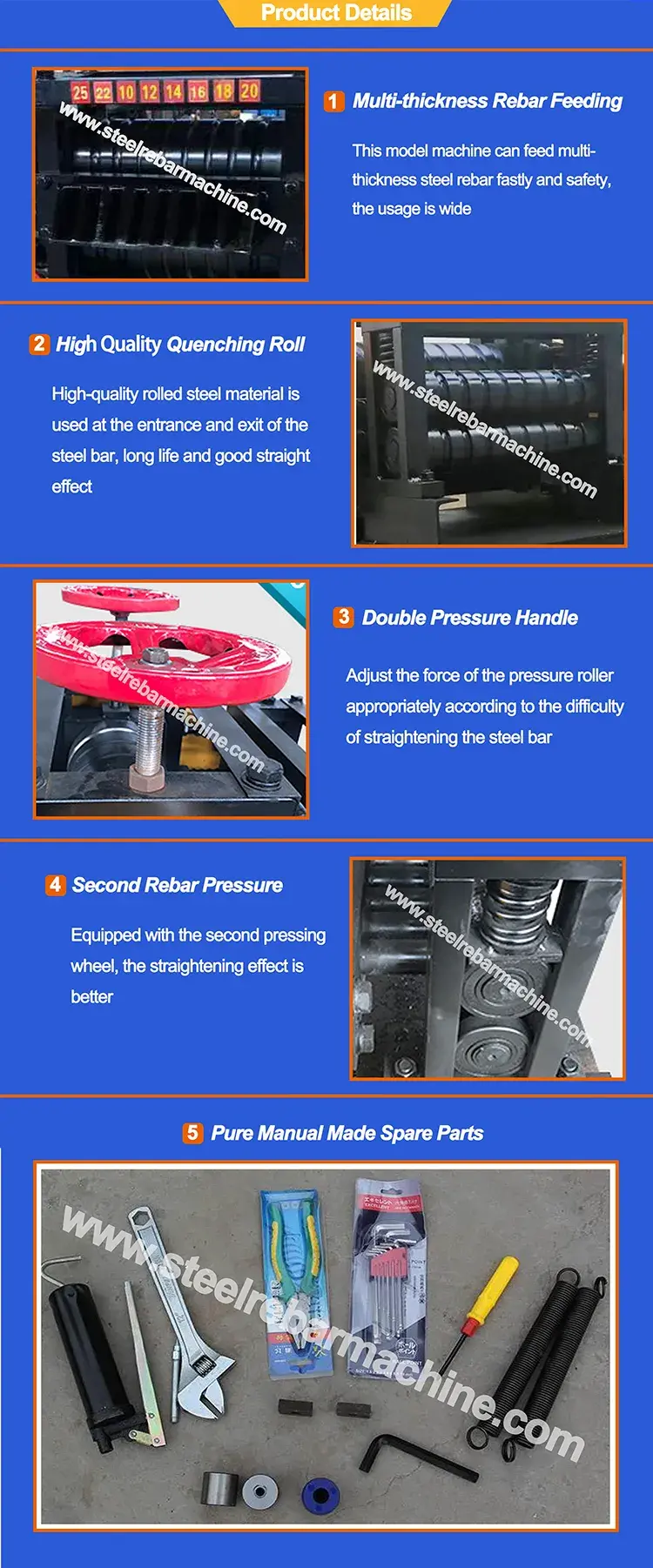

- Straightening Capability: The primary function of the waste rebar straightening machine is to straighten bent or twisted rebars to their original shape. This is achieved through a series of rollers and mechanical adjustments.

- Cutting Function: steel bar straightening machine includes a cutting function, allowing users to cut rebars to specific lengths as needed for various construction purposes.

- Feeding Mechanism: The scrap rebar straightening machine usually has an automated feeding mechanism that draws the rebar into the straightening unit.

- Adjustable Settings: Operators can adjust settings such as the diameter of the rebar being processed, the speed of straightening, and the degree of straightening required.

- Safety Features: Modern machines come equipped with various safety features, such as emergency stop buttons, protective covers, and automated shutdown in case of malfunctions.

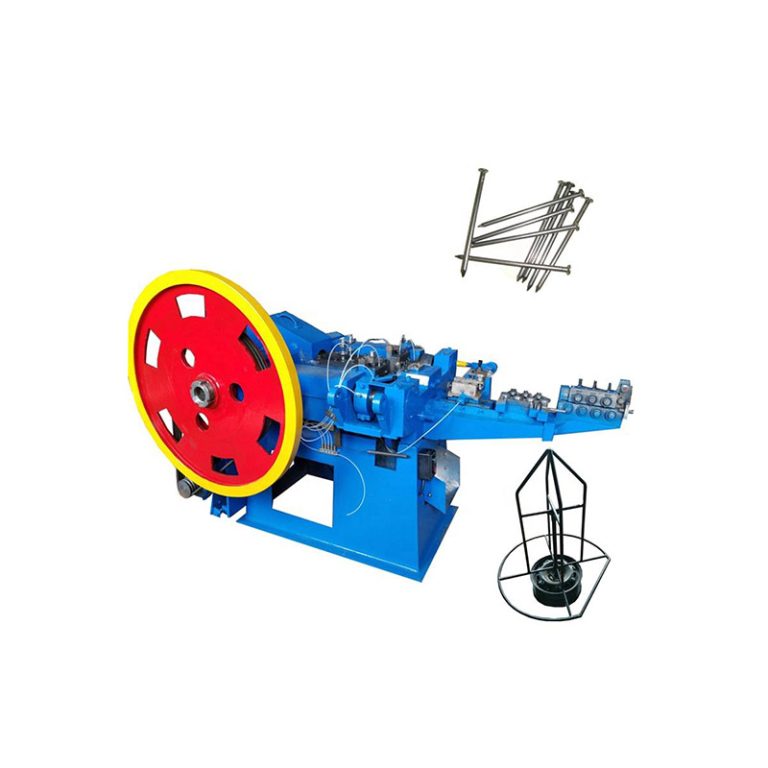

Related models of waste rebar straightening machine