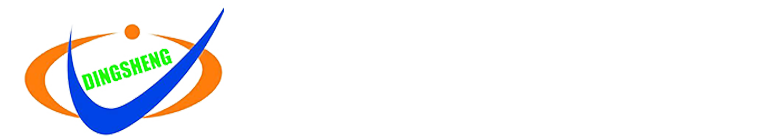

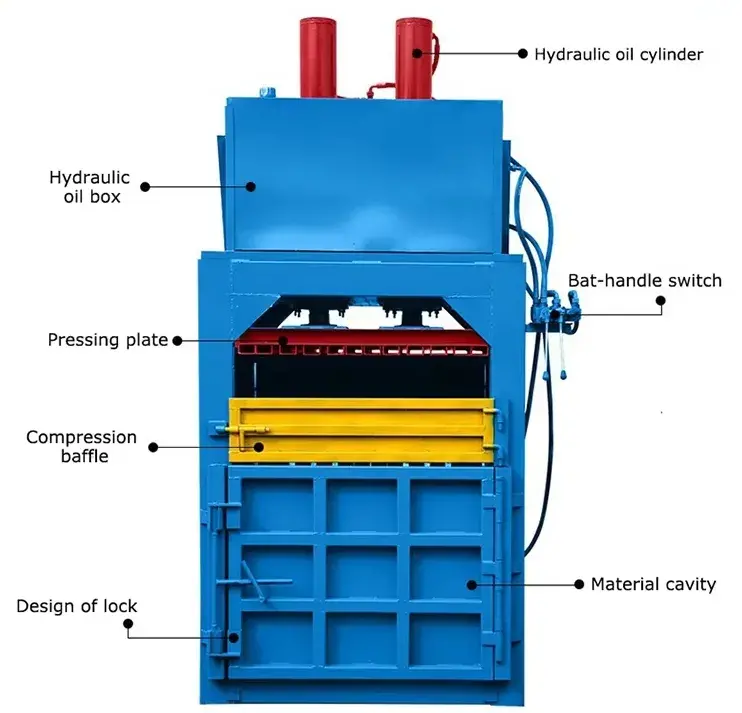

Waste paper baler is used for baling cartons, cotton yarn, plastic, waste plastic bottle, etc. It is designed as vertical structure, hydraulic Transmission, electrical control and manual binding. Usually the pressure force of this series is from 10 ton KN to 100 ton KN, the efficiency is 4 ~ 6 bags per hour. The weight of each piece is from 30 Kg to 500 Kg according to the material. Also, we can produce the machine according to the requirement from customer.

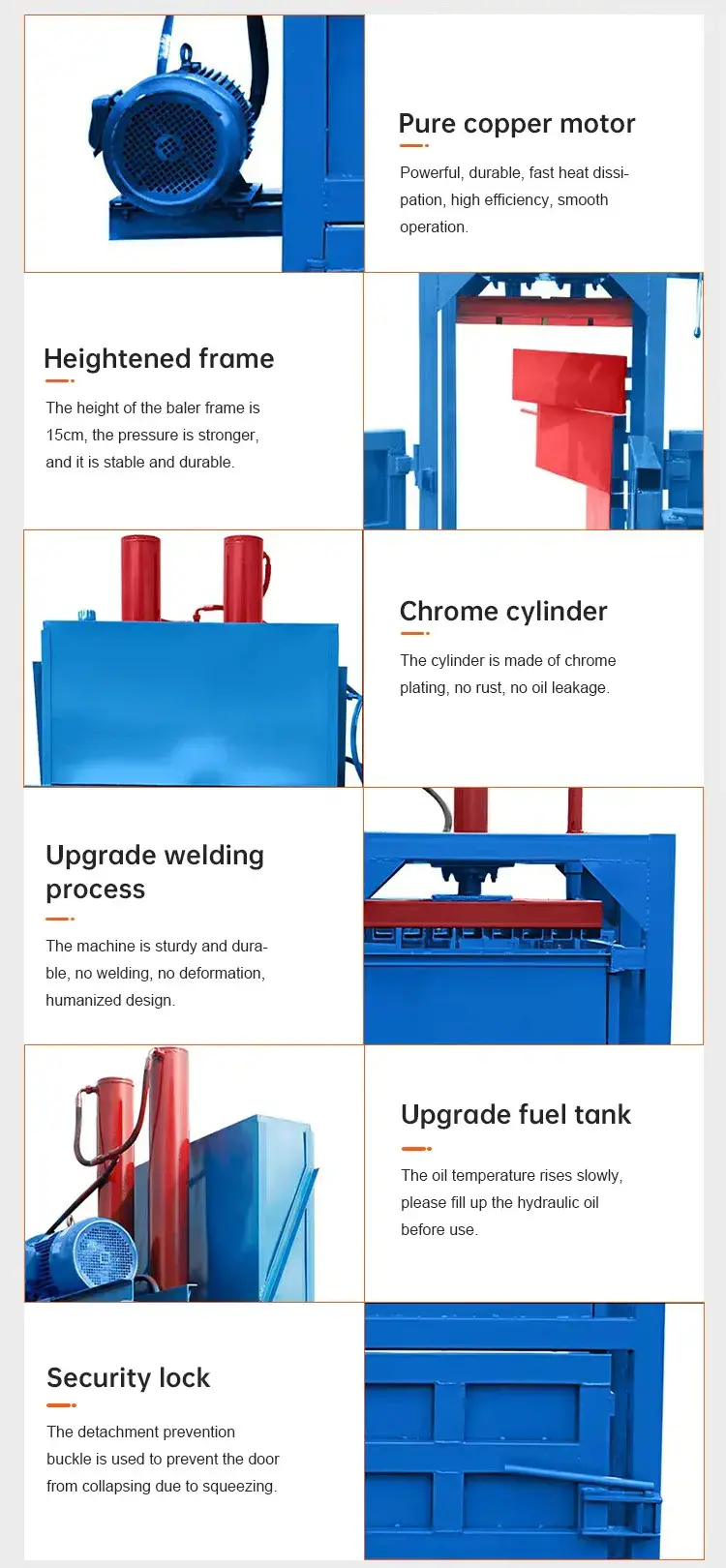

It is designed as vertical structure, hydraulic transmission,electrical control and manual binding. Materials after compression all have uniform external dimensions with tight and high density, which is space-saving and convenient to stock and transport. The working pressure is from 30T to 200T, we can also make the machine according to the requirement from customer.

The features of waste paper baler machine

- With a rotary closed cover structure, the opening area of the material box is large and it is especially convenient for the feeding of large and empty thin materials.

- Each moving part adopts hydraulic drive, working steadily, packing pressure is big, the bundle block is tight, and packing efficiency is high.

- The operation of the manual reversing valve is simple, convenient, safe, and reliable.

Why do we choose hydraulic waste paper baler packing press machine?

- Efficient waste management: By baling materials into compact bales, the machine helps to reduce the volume of waste generated, making it easier to store and transport.

- Cost savings: Baling materials can help businesses reduce waste disposal costs by optimizing storage space and facilitating easy recycling or disposal.

- Environmental sustainability: Vertical baling machines promote recycling and reduce the environmental impact of waste materials by facilitating their efficient processing and reuse.