CNC Tel Düzeltme ve Kesme Makinesi, çelik tel ve inşaat demirini düzeltme ve kesme işlemlerinde hassasiyet için titizlikle tasarlanmıştır. Bu çok yönlü makine, çeşitli tel türleri ve boyutlarını destekleyerek yüksek hızlı işleme ve tutarlı kalitede çıktı sağlar. Hem çelik tel düzeltme makinesi hem de inşaat demiri düzeltme makinesi olarak tasarlanan bu makine, otomatik çalışma ve sağlam yapıya sahiptir. Verimliliği artırmak için özelleştirilebilir konfigürasyonlarla sıkı endüstri standartlarını karşılar.

Tel düzeltme ve kesme makinesinin özellikleri

- Yüksek hassasiyet: Makinelerimiz gelişmiş düzeltme ve kesme teknolojisi kullanır.

- Yüksek verimli üretim: Yüksek hızlı işleme için tasarlanmış, dakikada yüzlerce metal teli işleyebilen, üretim verimliliğini önemli ölçüde artıran

- Güvenilir ve istikrarlı çalışma: Makinemiz sağlam ve dayanıklı bir yapısal tasarıma ve güvenilir bir besleme ve boşaltma sistemine sahiptir.

- En az üç yıl garanti, mühendisler devreye alma ve bakım için tesisinize gelecek ve düzenli olarak yerel ziyaretler gerçekleştirecektir.

Tel düzeltme ve kesme makinesinin çalışma süreci

- Besleme sistemi: Kullanıcılar, çeşitli tip ve boyutlardaki metal telleri makineye beslemek için pnömatik frenli tel disk veya elektrikli frenli tel disk seçebilirler.

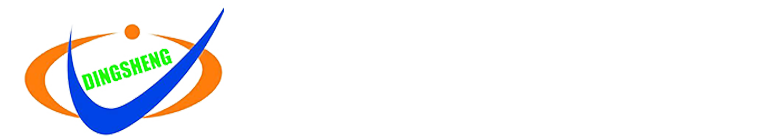

- Düzleştirme işlemi: Makine, yüksek hassasiyetle metal telleri düzleştirmek için hassas tasarımlı silindirler veya düzleştirme kalıpları ve sıkıştırma sistemleri kullanır ve böylece sıkı düzlük gereksinimlerini karşılar.

- Otomatik kesme: Önceden ayarlanmış uzunluk parametrelerine göre, makine her bir telin uzunluğunun doğru ve tutarlı olmasını sağlamak için otomatik olarak keser.

- Otomatik toplama sistemi: Toplama sistemimiz, düzleştirilmiş ve kesilmiş telleri otomatik olarak toplayabilir ve otomatik itme sistemi aracılığıyla telleri bir araya iterek bir sonraki paketleme veya işleme adımını kolaylaştırır.