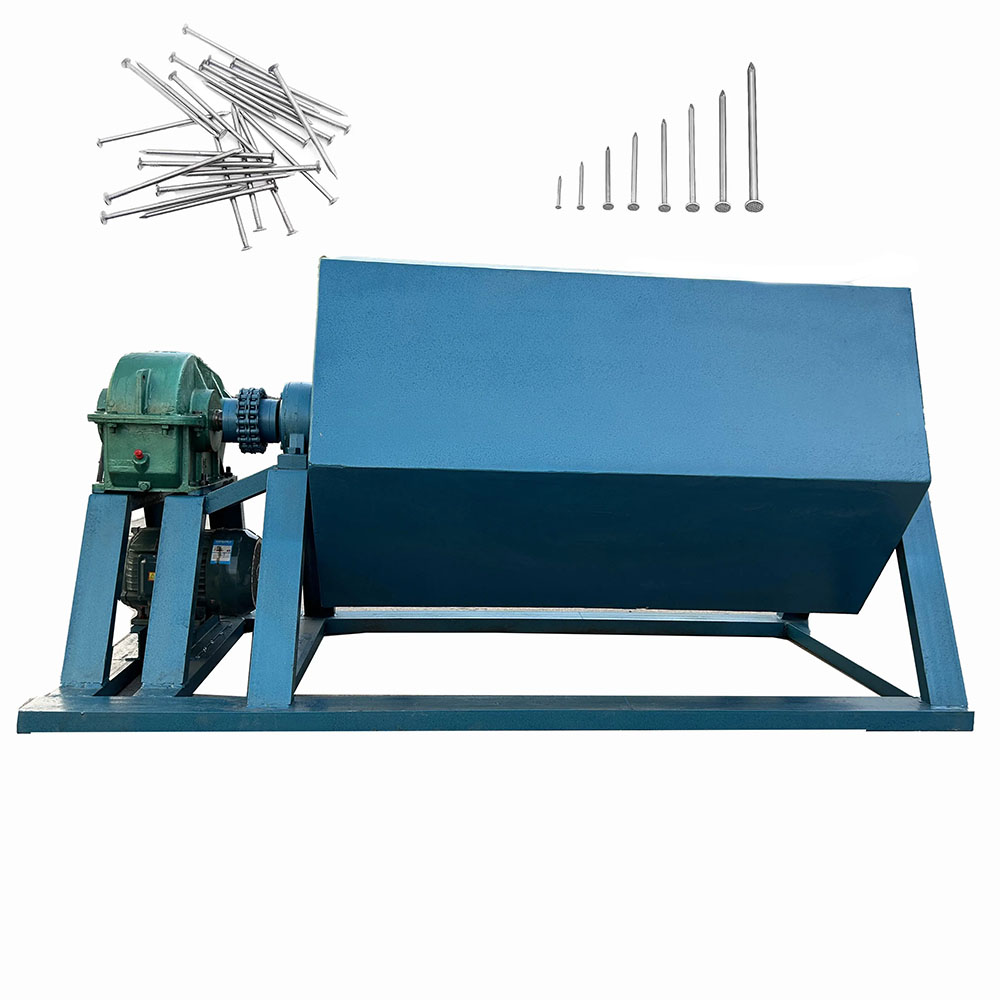

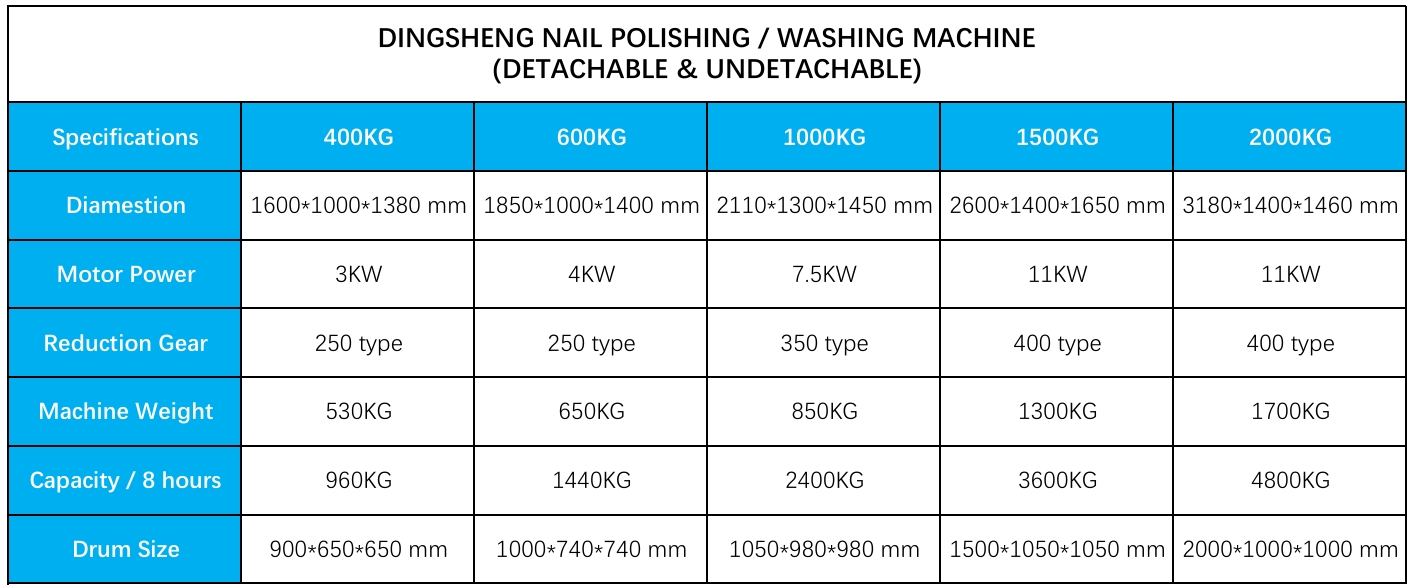

Steel nail washing machine is a high-efficiency polishing equipment, mainly suitable for deburring, derusting, rounding feet and bright polishing of metal and non-metal parts. The machine avoids the traditional multiple processes of shelling, pickling, washing, ash coating, drying, etc., shortens the production cycle, and significantly improves the production efficiency. Generally one set of steel nail washing machine with 1000 kg capacity can confiure two sets of steel nail making machine, it‘s eneough to cleaning steel nails.

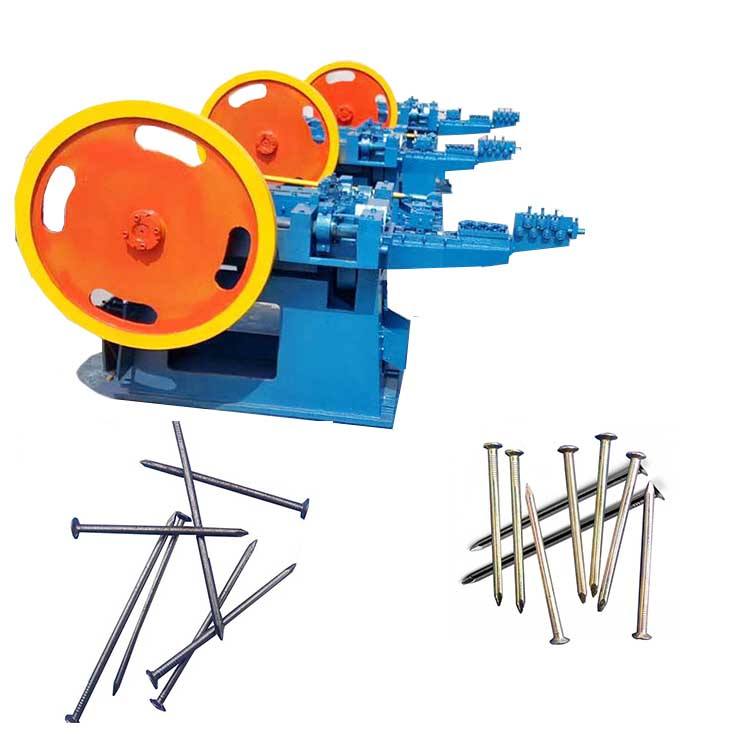

Steel nail washing machine is also known as nail polishing machine, steel nail grinding machine, etc. It removes burrs and polishes the nails processed by the nail making machine through high-speed rotation and friction. It is used to remove rust and polish the semi-finished round nails that have just been produced. Nail washing machine is an indispensable equipment in the nail making industry. And in the whole nail production line, the market is very hot with positive profit around the world, you can look through our nails plant profit report.

The production process of steel nail washing machine

- Put the common nails in the polishing machine drums.

- Put some sawdust/ wood powder/stives in the drums also.

- Then seal the cover plate, keeping rolling for 90 minutes normally.

- After 90 minutes change the cover plate with holes, to make the powder washing out.

- Meanwhile, add the wax with water in the polishing machine drums (WIRE NAILS POLISHING MACHINE).

- Then keep polishing for 90 minutes again.

- The last step is to take out of nails.