Round steel nail making machine is an industrial device used to manufacture steel nails from wire. These machines can vary in terms of automation, capacity, and complexity, and they are essential for producing nails used in construction, carpentry, and various other applications. Dingsheng machine manufacturer can make the whole steel wire nail product line, such as nail polishing machine, nail grinder machine, steel wire drawing machine, butt-welding machine and roller tip machine. Our round steel nail making machine arrived in many countries like Bangladesh, Uzbekistan, India, Ukraine, Russia, Egypt and so on.

Production process of round steel nail making machine

We should draw the raw material of wire rods of 6.5 mm or 5.5 mm diameter (usually 2-3 tons per coil), to small wire coils (200-300 kg per coil) of diameter such as 4.5 mm, 4.1 mm, 3.4 mm, 2.8 mm, etc needed for making nails by the wire drawing machine, after this, put the small wire coils on a wire reel, from which the steel wire was fed into the round steel nail making machine to make nails, after the wire is cut to nails, it needs to polish the nails to remove the iron dust on the nail shaft and make it become bright and good looking, then packaging.

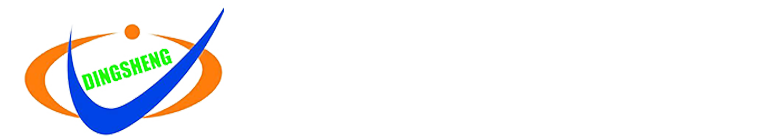

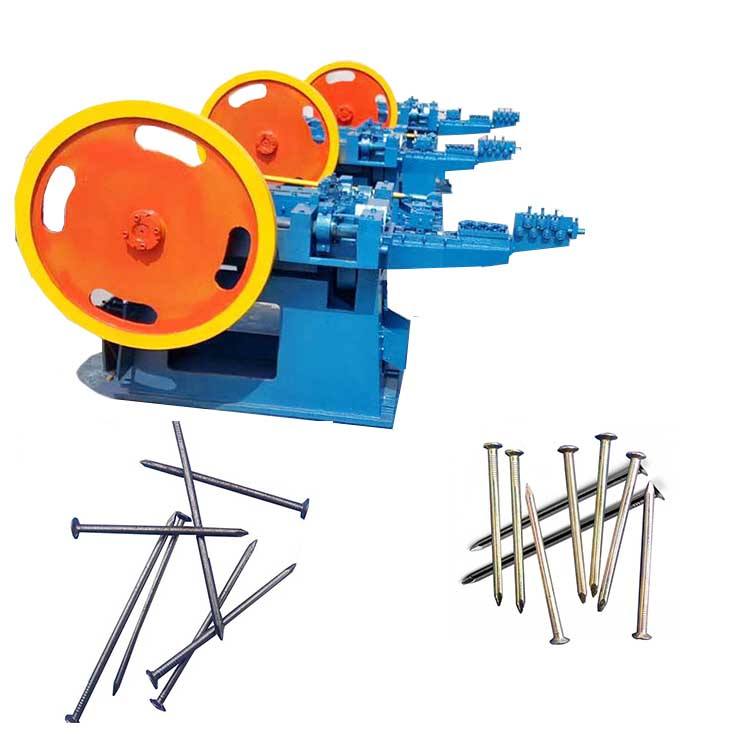

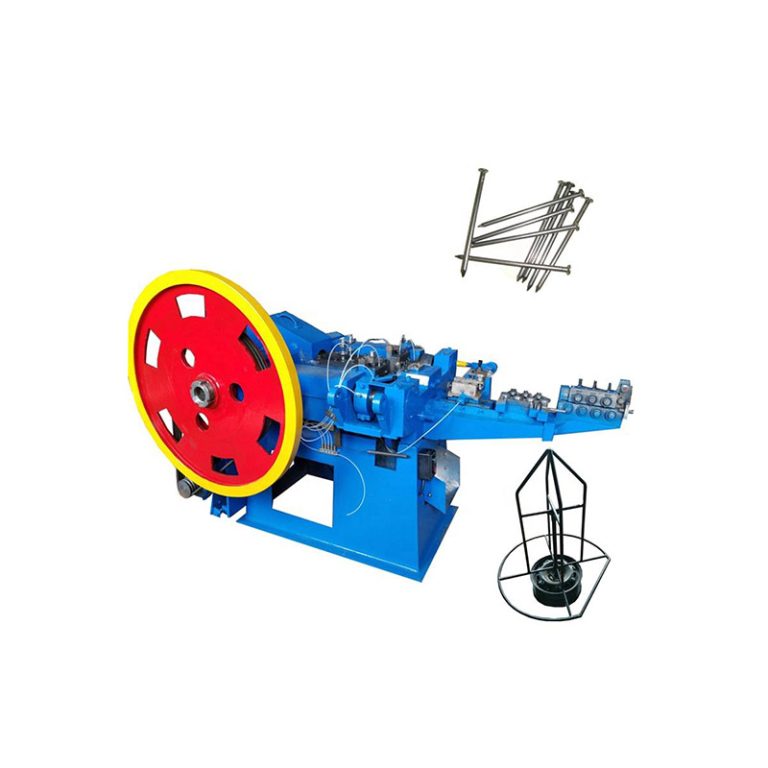

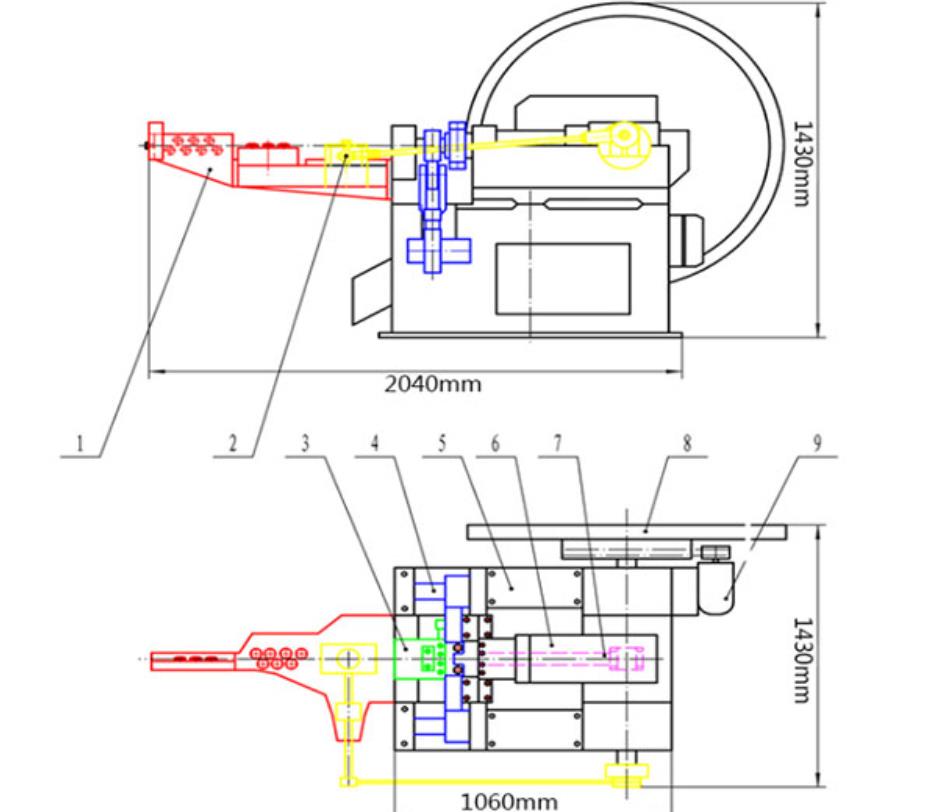

Round steel nail making machine structure:

The main structure of the nail-making machine, including the big wheel, mainframe, motor, discharge hopper, wire feeding mechanism, straightening mechanism, punching mechanism, mold mechanism, nail cutter cutting Mechanism, and gear transmission mechanism.

The features of round steel nail making machine

- This wire nail making machine adopts plunger type structure to ensure the high speed, low noise, less blunt acoustic.

- It has advanced design, compact structure, beautiful appearance, easy operation, safety and other features.

- Nails making machine is adopt of bearing and oil pipe lubricating structure to ensure the high working speed .

- Energy saving, stable and reliable performance. Quality up to standard, the device has small volume, flexible to move, low noise, low consumption, easy installation, etc.

- Product application: The common nails is widely used in construction and decoration, such as softand hard wood, bamboo ware, ordinary plastic, mud wall, repair furniture, packing wooden cases, etc.

How to make nails with round steel nail making machine?

- Wire Drawing: Draw the wire rods from 6.5/5.5mm to a smaller diameter for example 4.5mm, 3.4mm for making nails.

- Nail Making: Feed the 4.5/3.4mm black steel wire to make nails.

- Nail Polishing: Add sawdust in the nail polishing drum to polish the nails and make them bright.

- Packing: Packaging the nails in bags or cartons.

- China steel nail making machine is the most important equipment in the nail making process. If there is already drawn iron wire available, then only a nail production machine itself can

- complete the nail-making job. According to the different nail sizes that need to be made, choose the appropriate nail machine model.