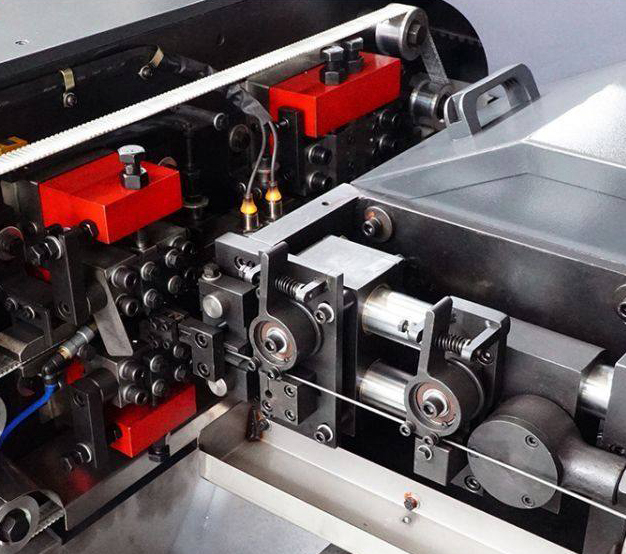

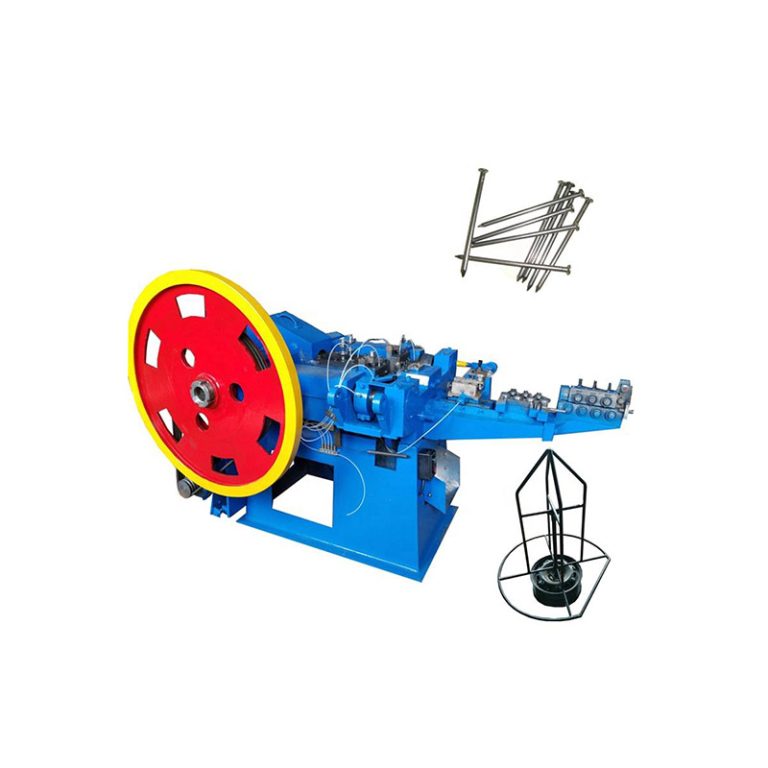

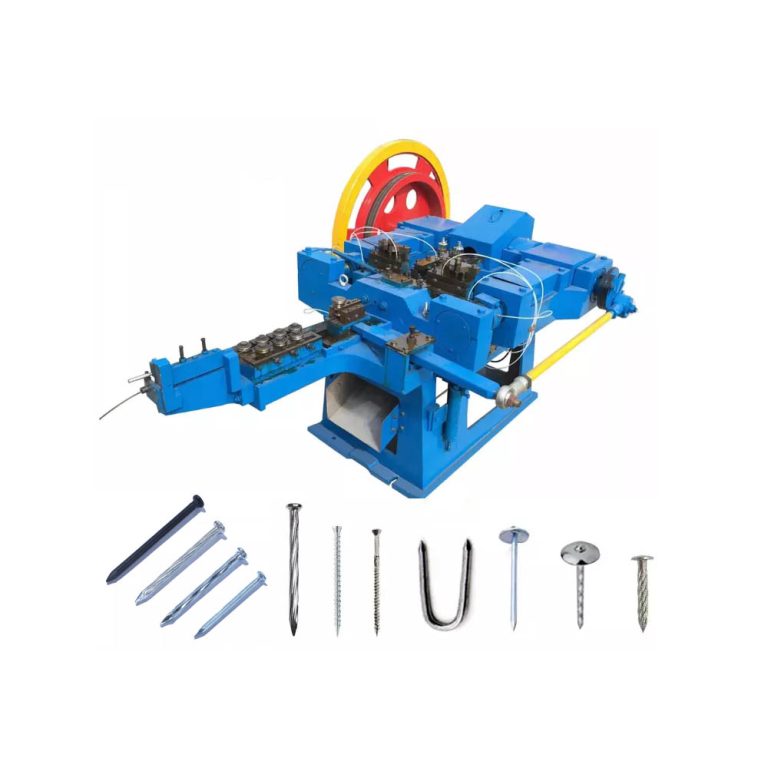

Automatic high speed steel nail making machine is for making nails with large batch, high precision and high production capacity, max. output could reach 800 pcs/min, use less manpower, maximize the production cost for manufacturers.

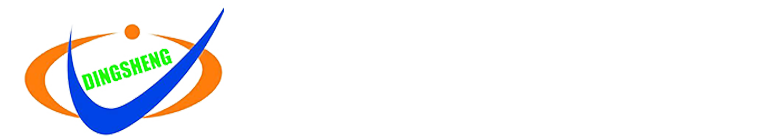

Our high speed steel nail making machine comes with beautiful appearance, smooth lines, scientific and reasonable structure, and the center slider clearance adjustment adopts wedge iron adjustment, which is more convenient for operation and maintenance. Lubrication adopts automatic oil supply system, making the work more stable and reliable, the noise is greatly reduced, and the working conditions are greatly improved.

High speed steel nail making machine realizes PLC computer program control automatic operation, can set the length of the nail, the nail making time, the speed of the nail making machine by computer, and it is more accurate for the production of lengthened nails. It is highly praised by customers due to excellent performance and sophisticated design.

The main characteristics of high speed steel nail making machine

- The nail length can be well controlled.

a. The machine equipped with sensor for detecting longer or shorter nails

b. Active wire feeding, can ensure straight shank and consistent length, no matter what the wire coil’s weight is. - Metal scraps can be well separated

a. Effectively protect the nail conveying belt

b. Ensure the nail head with good and consistent shape - High quality nails: consistent nail head and shank length (tolerance 0.5 mm), defective rate 1/100000, which is very good for coil nail collating and strip nail making.

- Easy operation and high efficient: the machine is fully automatic and runs stably.

- Automatic oiling system with oil pump

- With seven alarming sensors to protect the machine and ensure the nail quality

- Low maintenance cost

- Labor cost saved by 50%–70% for nail making