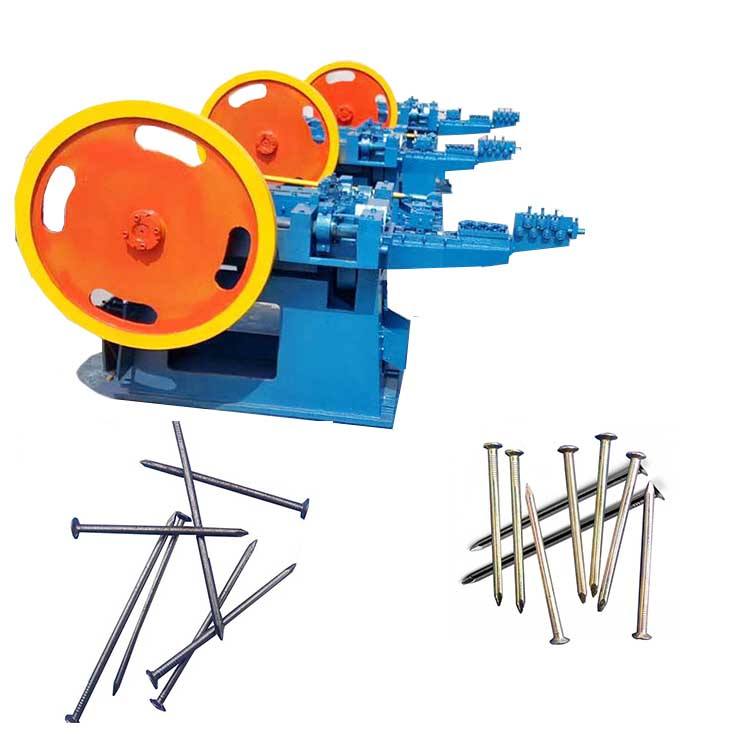

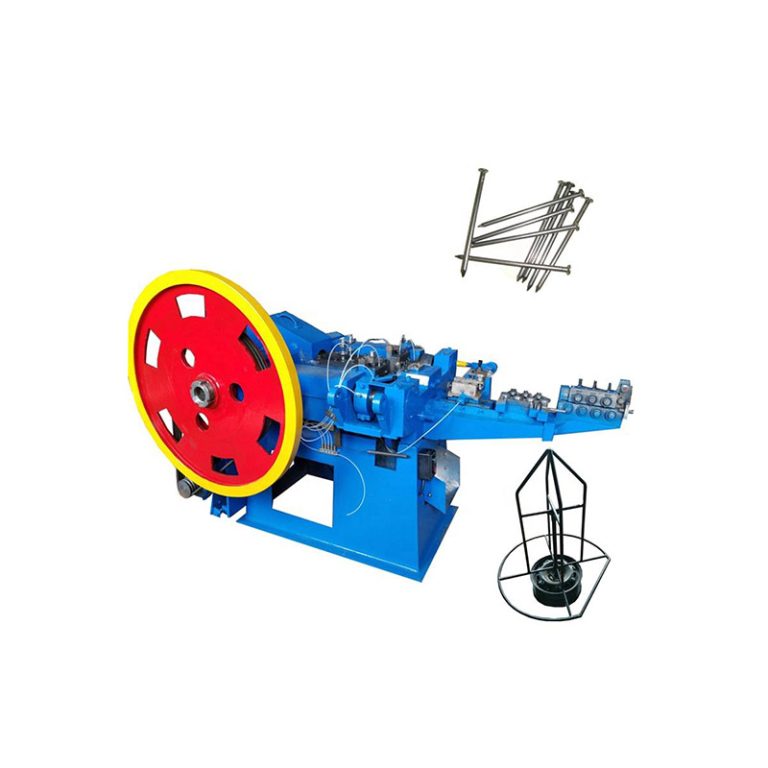

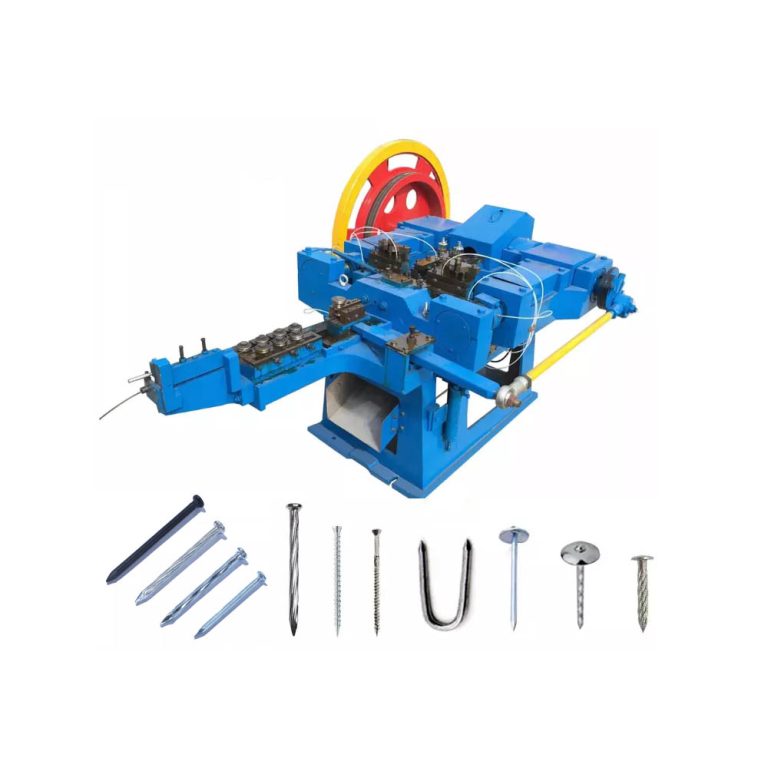

High speed iron nail making machine is a specialized piece of industrial equipment designed to manufacture iron nails efficiently and with high precision. Our iron nail making machines are commonly used in manufacturing facilities where large volumes of nails are required for construction, carpentry, and general hardware applications. Our high speed iron nail making machine automates the process of producing iron nails from steel wire, which can operate continuously and are designed to maximize output while maintaining uniform quality.

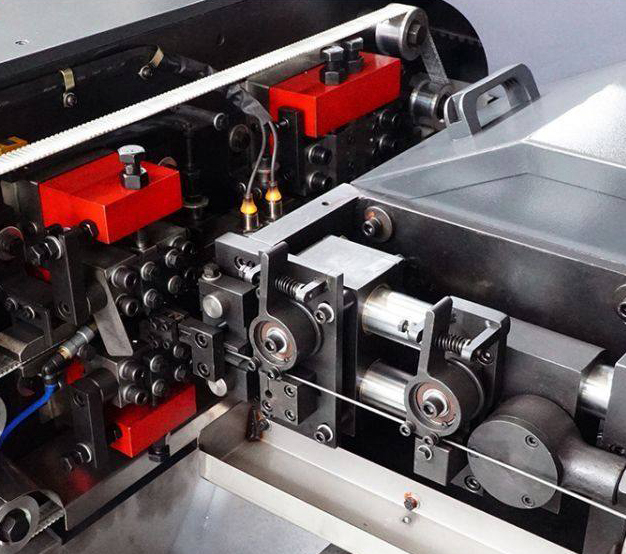

High speed iron nail making machine draws wire from a coil, straightens it, cuts it to the desired length, and then forms the nail head and point in a continuous process. This is achieved through synchronized mechanical operations, often enhanced by servo motors and electronic controls in modern systems.

The main characteristics of High speed iron nail making machine

- The nail length can be well controlled.

a. The machine equipped with sensor for detecting longer or shorter nails

b. Active wire feeding, can ensure straight shank and consistent length, no matter what the wire coil’s weight is. - Metal scraps can be well separated

a. Effectively protect the nail conveying belt

b. Ensure the nail head with good and consistent shape - High quality nails: consistent nail head and shank length (tolerance 0.5 mm), defective rate 1/100000, which is very good for coil nail collating and strip nail making.

- Easy operation and high efficient: the machine is fully automatic and runs stably.

- Automatic oiling system with oil pump

- With seven alarming sensors to protect the machine and ensure the nail quality

- Low maintenance cost

- Labor cost saved by 50%–70% for nail making