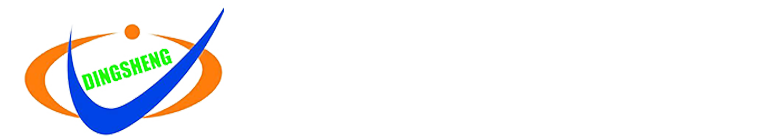

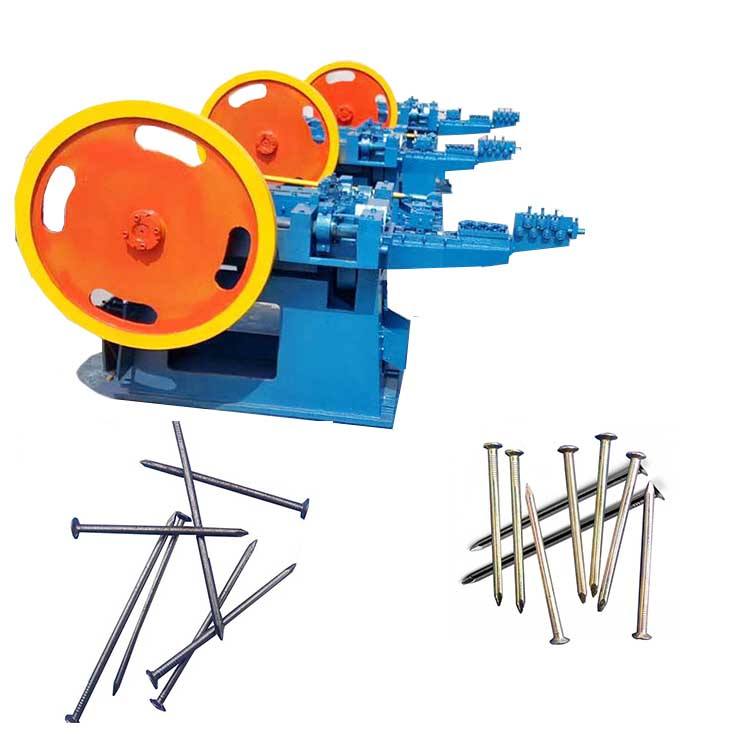

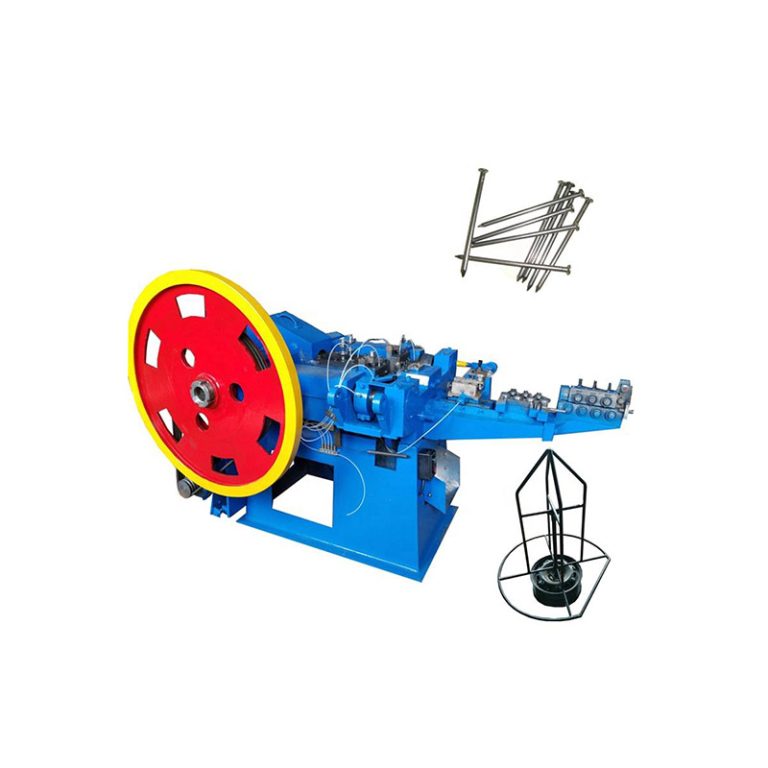

Automatic steel wire nail production line an industrial setup designed to produce wire nails. This process involves several stages and different types of machinery to transform steel wire into finished nails and meets the mass production of wire nails. Wire nails, also called common nails, are the backbone of many construction and manufacturing projects. Because of their good corrosion resistance, long service life, fast nailing speed, and simple operation, wire nails are very popular in the application of furniture, construction, home decoration and woodwork.

The features of steel wire nail production line

- Wire Uncoiling & Straightening: Unwinds the coiled steel wire (raw material) and straightens it to a uniform, linear shape, ensuring consistent nail length and straightness.

- Continuous Operation: Once set up, the machine runs continuously with only periodic raw material (steel wire) replenishment, achieving production speeds of 450 nails per minute (depending on model and nail size).

- Precision Cutting Mechanism: Equipped with hardened, high-precision cutting tools (e.g., tungsten steel blades) and length-adjustment knobs, ensuring nail length variation of ≤ ±0.5mm.

- Nail Length: Typically ranges from 10mm (3/8 inch) to 200mm (8 inches); adjustment is done via the cutting mechanism and wire feed speed.

- Hardened Components: Critical parts (cutting blades, forging dies, sharpening wheels) are made of wear-resistant materials (e.g., chrome-vanadium steel, tungsten carbide) to extend service life and reduce maintenance.

- Easy Maintenance: Modular design allows quick access to components (e.g., replaceable blades, lubrication points) for cleaning, repair, or part replacement.