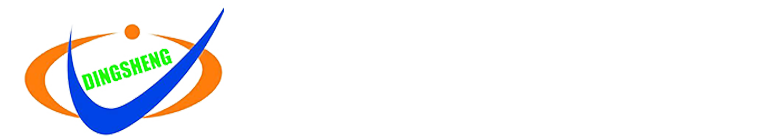

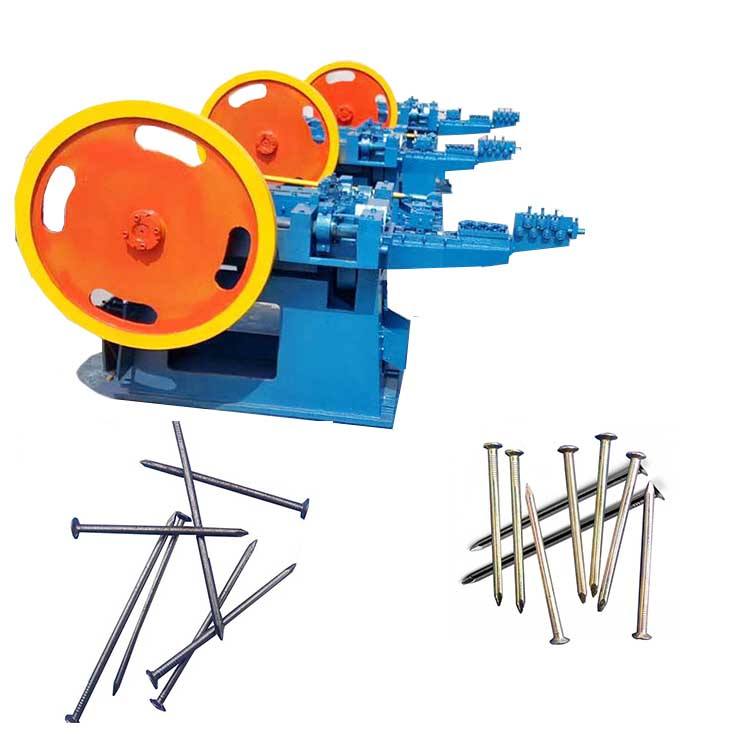

We are manufacturer of making best steel wire nail machine over 10 years in the whole nail production line. We sell our machine to Turkey, Russia, Egypt, Saudi Arabia, Czech Republic, Poland, Mexico, Serbia, Vietnam and many other countries. Best steel wire nail machine is a mechanical device used in the manufacturing industry to produce nails from various types of metal wire. It automates and streamlines the nail production process, significantly increasing efficiency and productivity compared to manual nail production.

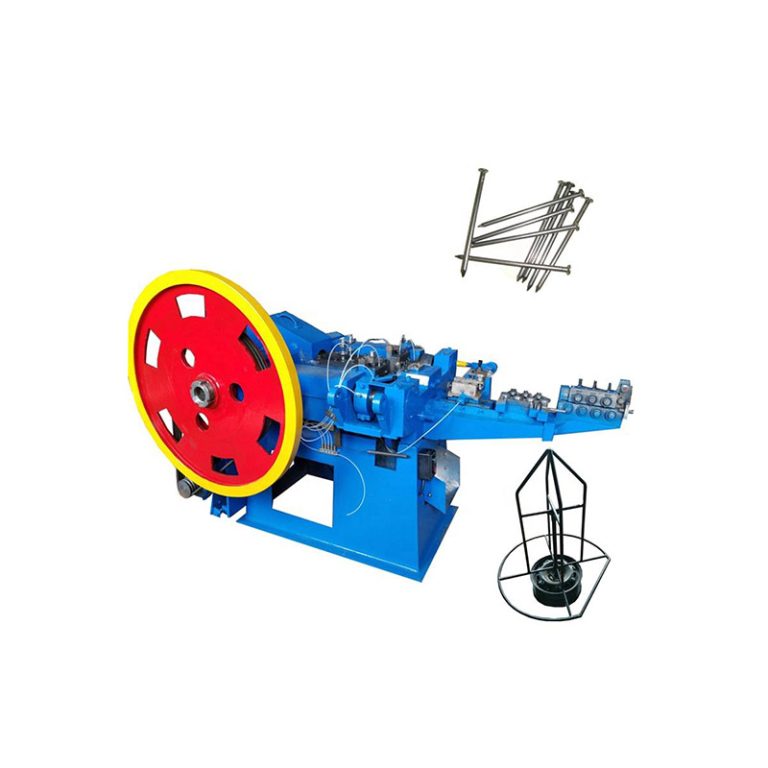

The machine typically consists of several key components, including a wire feeding mechanism, wire straightening system, wire cutting mechanism, nail forming tooling, and a nail collection system. The process begins with feeding a coil of metal wire into the machine. The wire is straightened, cut, and then fed into a set of dies or tooling that shapes it into the desired nail shape and size. The formed nails are then collected and discharged through a chute or conveyor system.

The features of best steel wire nail machine

- Wire Uncoiling & Straightening: Unwinds the coiled steel wire (raw material) and straightens it to a uniform, linear shape, ensuring consistent nail length and straightness.

- Continuous Operation: Once set up, the machine runs continuously with only periodic raw material (steel wire) replenishment, achieving production speeds of 450 nails per minute (depending on model and nail size).

- Precision Cutting Mechanism: Equipped with hardened, high-precision cutting tools (e.g., tungsten steel blades) and length-adjustment knobs, ensuring nail length variation of ≤ ±0.5mm.

- Nail Length: Typically ranges from 10mm (3/8 inch) to 200mm (8 inches); adjustment is done via the cutting mechanism and wire feed speed.

- Hardened Components: Critical parts (cutting blades, forging dies, sharpening wheels) are made of wear-resistant materials (e.g., chrome-vanadium steel, tungsten carbide) to extend service life and reduce maintenance.

- Easy Maintenance: Modular design allows quick access to components (e.g., replaceable blades, lubrication points) for cleaning, repair, or part replacement.

If you want to know more about the whole iron nail produiction line, you can click here.