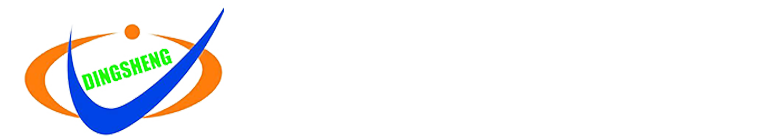

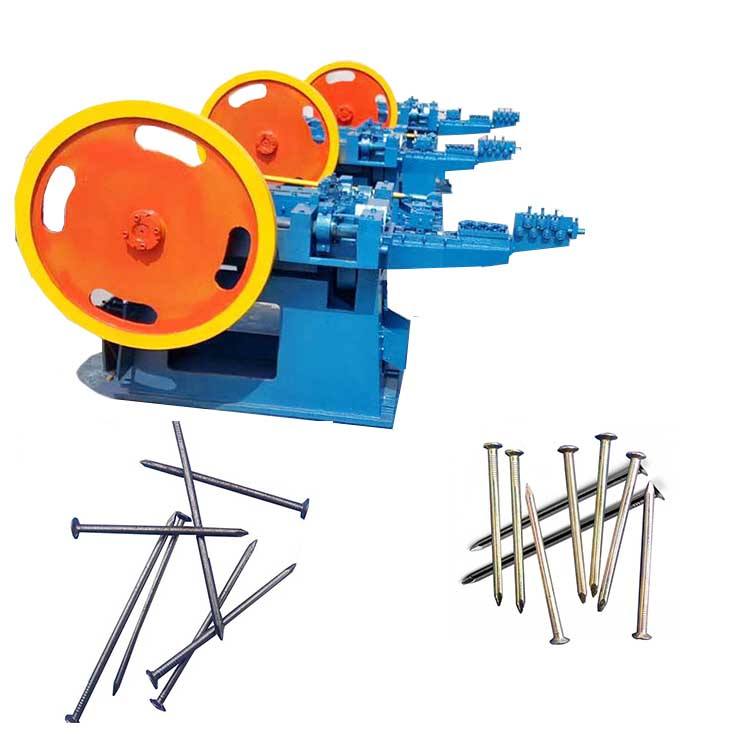

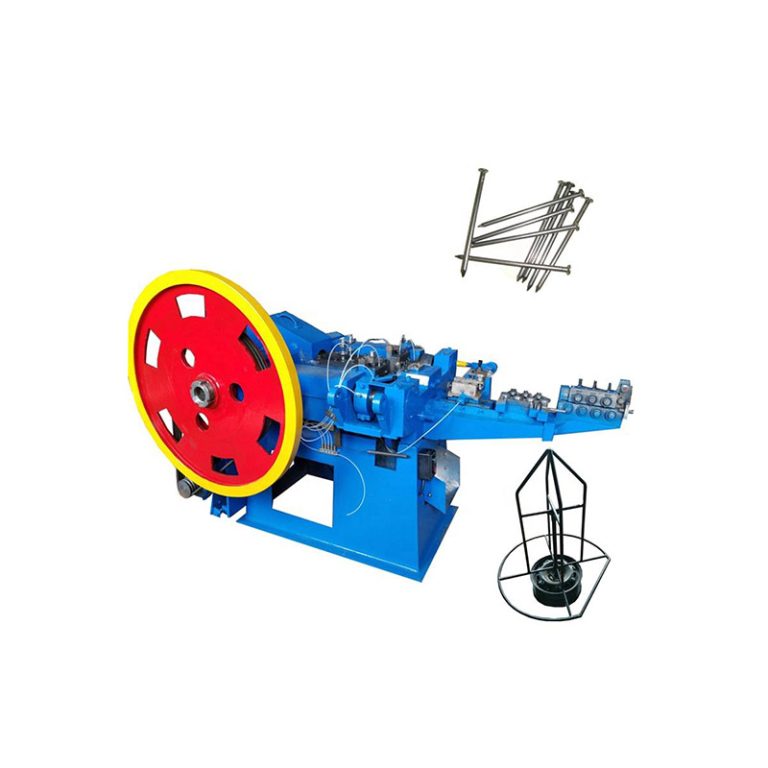

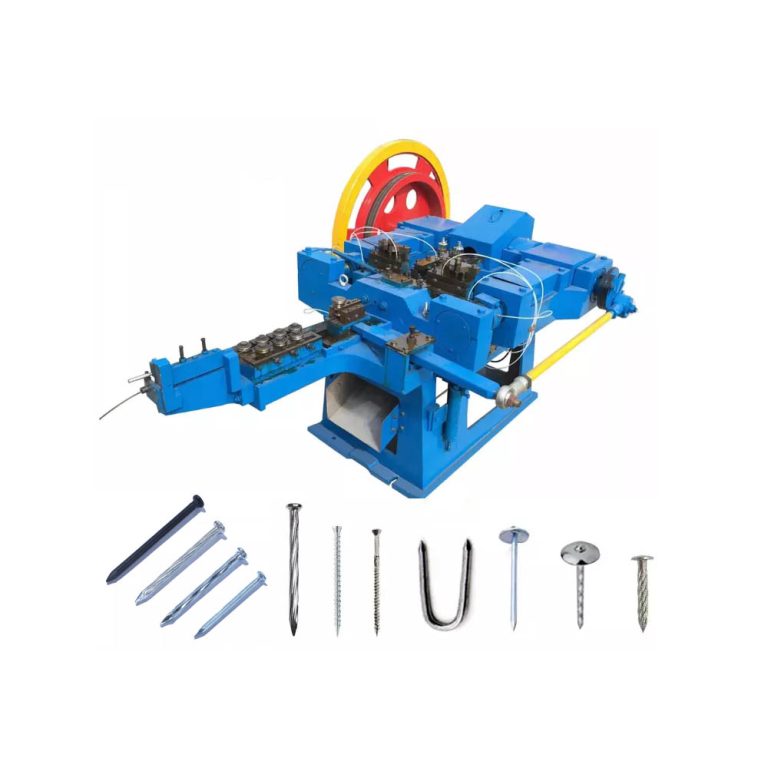

Baling wire ties making machine is a specialized piece of equipment designed to produce baling wire ties, which are used for securing bales of various materials such as cardboard, paper, hay, and other recyclables. These machines are essential in industries where large quantities of materials need to be compacted and secured for storage, transportation, or recycling.

Double loop bale tie wire machine is recommended for producing highly compressible materials—tires, foam, scrap metal. Bright Basic ties are available in 9-gauge to 13.5-gauge, lengths up to 19 feet, and various ties per bundle.

The features of baling wire ties making machine:

- Baling wire ties making machine automates the process of feeding, cutting, and tying the wire around the tire bales, significantly reducing manual labor and increasing productivity.

- Equipped with powerful motors and precise control systems, these machines can process large quantities of tires quickly, making them suitable for high-volume operations.

- Baling wire ties making machine allow for adjustments in wire tension, bale size, and tying configurations to accommodate different types and quantities of tires.

- Built to handle the tough conditions of recycling plants and waste management facilities, these machines are designed for longevity and minimal maintenance.

- Baling wire ties making machine come with safety mechanisms to protect operators from accidents, including emergency stop buttons and protective guards.

What fields is baling wire ties making machine used in?

- Recycling Facilities: The primary application is in recycling centers where used tires are processed for reuse or disposal. The bales can be transported more efficiently and take up less space.

- Waste Management: In waste management operations, these machines help manage tire waste by compacting it into manageable bales, reducing the volume and making it easier to handle.

- Logistics and Transportation: Compacted tire bales are easier to transport, reducing logistics costs and improving the efficiency of waste and recycling processes.

Why do we choose baling wire ties making machine?

- Automation of the tying process reduces the need for manual labor, allowing for faster processing times and higher throughput.

- Bale tie wire machine for tire provide consistent tying quality, ensuring that each bale is securely bound and less likely to come apart during handling and transportation.

- By reducing labor costs and improving efficiency, these machines offer a cost-effective solution for managing large volumes of tires.

- Efficient tire bailing and recycling processes contribute to better waste management practices, reducing the environmental impact of tire disposal.

Baling wire ties making machine is an essential tool in the tire recycling and waste management industry. By automating the binding process, it enhances efficiency, reduces labor costs, and ensures the secure handling of tire bales. Investing in such a machine can significantly improve operational efficiency and contribute to more sustainable waste management practices.