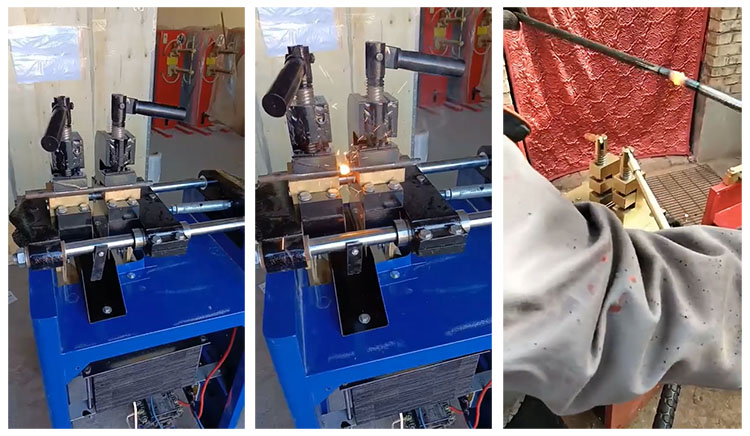

Steel wire butt welder machine is a specialized device used to join two pieces of steel wire by heating the ends and pressing them together until they fuse, which is commonly used in industries where continuous lengths of wire are required, such as in the production of wire mesh, fencing, drawing wire, and other wire-based products. Butt welding machine is one kind of manual lever pressuring type of welding, the welding pressure is by way of manual control lever on the workpiece to achieve the butt flash butt welding and resistance butt welding;

Mainly used for butt welding variety of steel and Non-ferrous metals,such as low carbon steel, carbon steel, stainless steel and nonferrous metal round wire, flat wire, round steel, flat steel, rebar steel, and so on; Steel wire butt welder machines are crucial in industries requiring continuous wire lengths. They offer a strong, efficient, and cost-effective method for joining wire ends, enhancing productivity and product quality.

Why should we choose wire butt welder machine?

- Strong Joints: Creates a durable and reliable bond between wire ends.

- Efficiency: Reduces the need for additional fastening methods or materials.

- Versatility: Can be used on various diameters and types of wire.

- Cost-Effective: Minimizes material waste and reduces production time.

Which fields is the wire butt welder machine widely used?

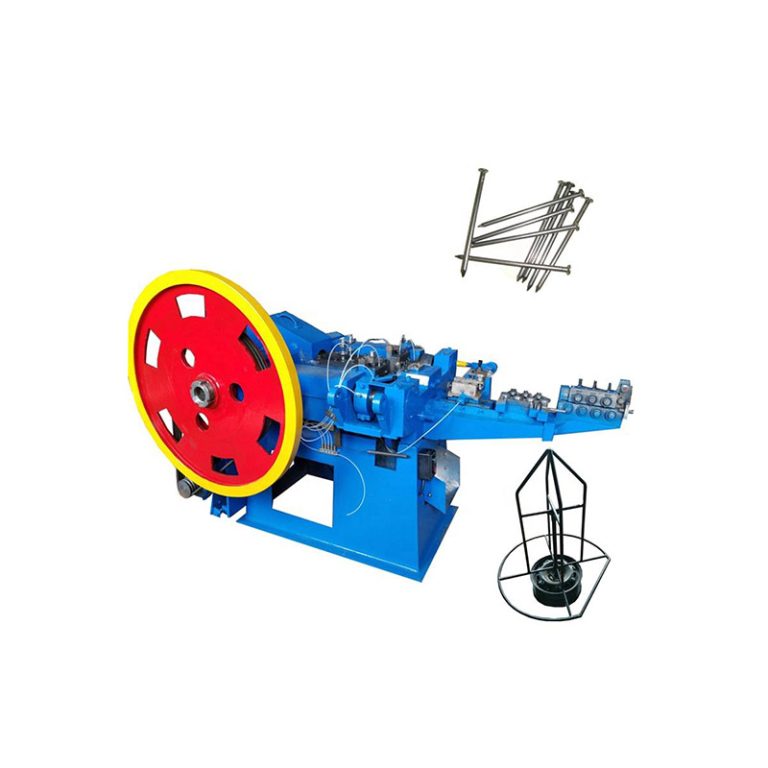

- Wire Drawing Mills: Joining wire ends during the drawing process.

- Wire Mesh Production: Continuous production of mesh without stopping for wire changes.

- Cable Manufacturing: Joining wire strands for cable production.

- Automotive: Producing wire components for vehicles.

How should we operate wire butt welder machine?

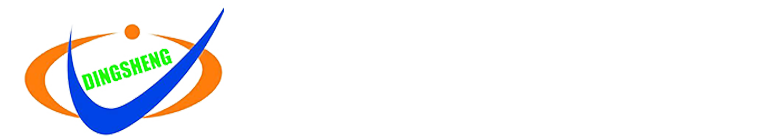

- Preparation: The wire ends are cut cleanly and clamped in the welding electrodes.

- Heating: Electrical current passes through the wire ends, heating them to a plastic or molten state.

- Pressing: The pressure mechanism forces the heated wire ends together.

- Cooling: The welded joint is cooled, often using a cooling system to ensure a strong bond.

- Inspection: The weld is inspected for quality, sometimes using non-destructive testing methods.