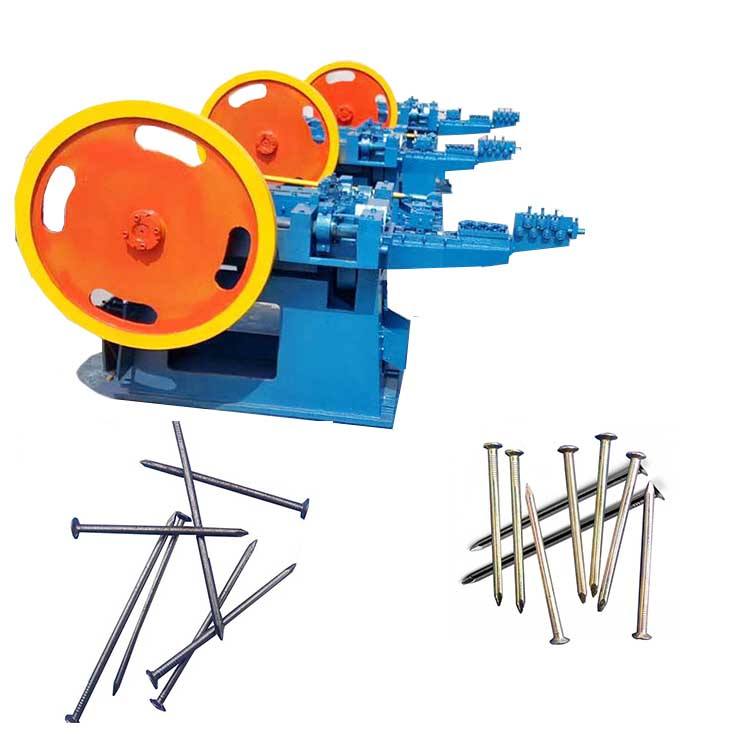

Steel nail knife sharpening grinder machine is a specialized tool designed for sharpening knives and other cutting tools of steel nail making machine with precision and efficiency. Wire nail machine knives sharpening and production is spent very much time and highly expensive job.

Everytime when the knives has blunted, it is necessary to heating until it becomes ember to solve rigidity. After processing of grinding or milling machine, heat treatment is required again. However, during these operations sharp knife surfaces burn or the material strength can be lost. Thanks to Wire Nail knives sharpening machine, it is sufficient once for knives annealing and heat treatment. As a result of This, steel nail knife sharpening grinder machine will be saved your time and expenses.

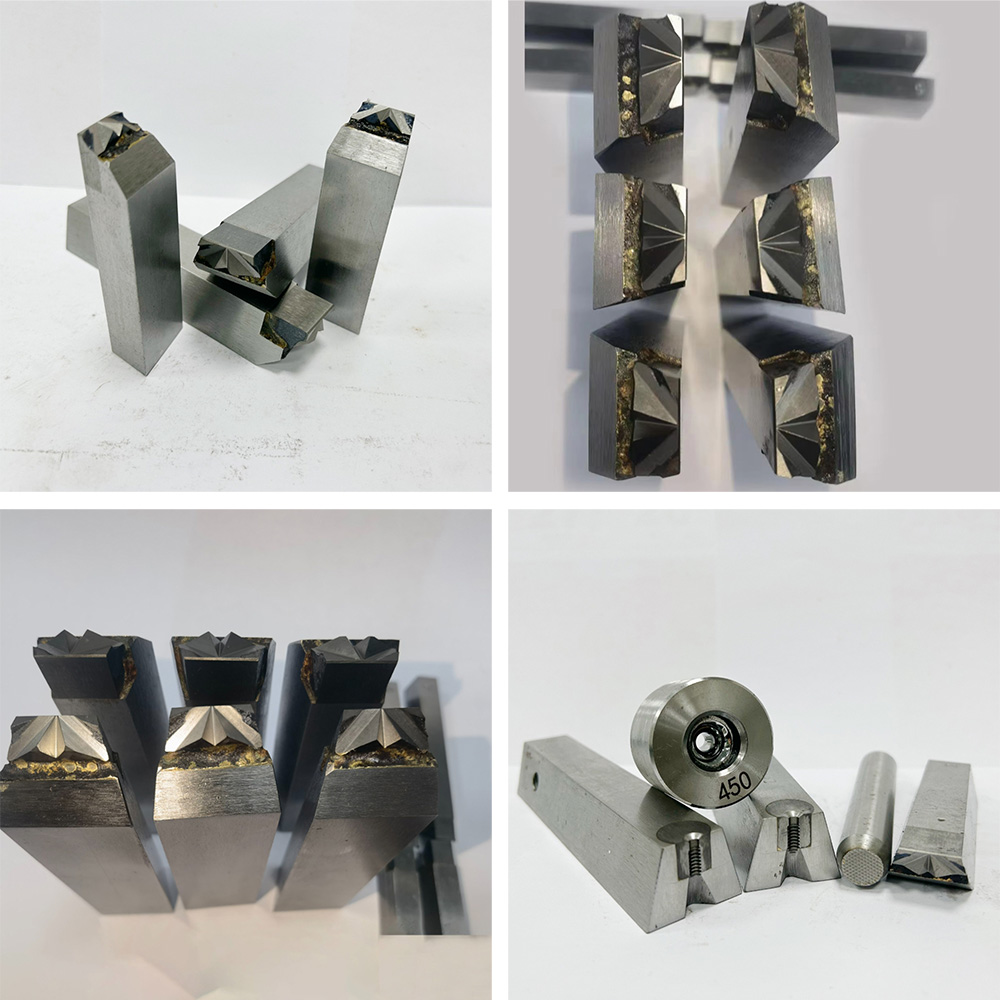

The components of steel nail knife sharpening grinder machine

- Grinding Wheel: The central component of the machine is the grinding wheel, typically made of abrasive materials like aluminum oxide or silicon carbide. The grinding wheel rotates at high speed to sharpen the edges of the knife.

- Motor: A powerful electric motor drives the grinding wheel. The motor’s power and speed determine how quickly and effectively the machine can sharpen the knife.

- Adjustable Guide: Many machines come with an adjustable guide to hold the knife at the correct angle during sharpening. This ensures a consistent edge and prevents uneven sharpening.

- Cooling System: High-speed grinding generates heat, which can damage the knife’s temper. Some machines are equipped with a cooling system, such as a water reservoir, to keep the blade cool during the sharpening process.

- Safety Features: These may include protective guards, anti-slip bases, and emergency stop buttons to ensure safe operation.

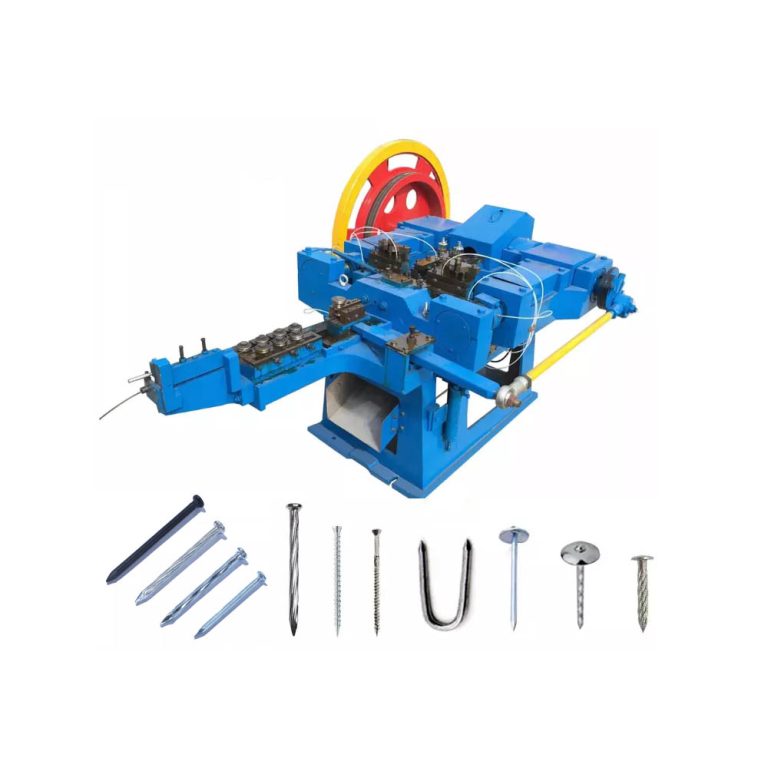

- Versatility: While primarily used for sharpening knives, many of these machines can also be used for other tools, such as scissors, chisels, and even steel nails.

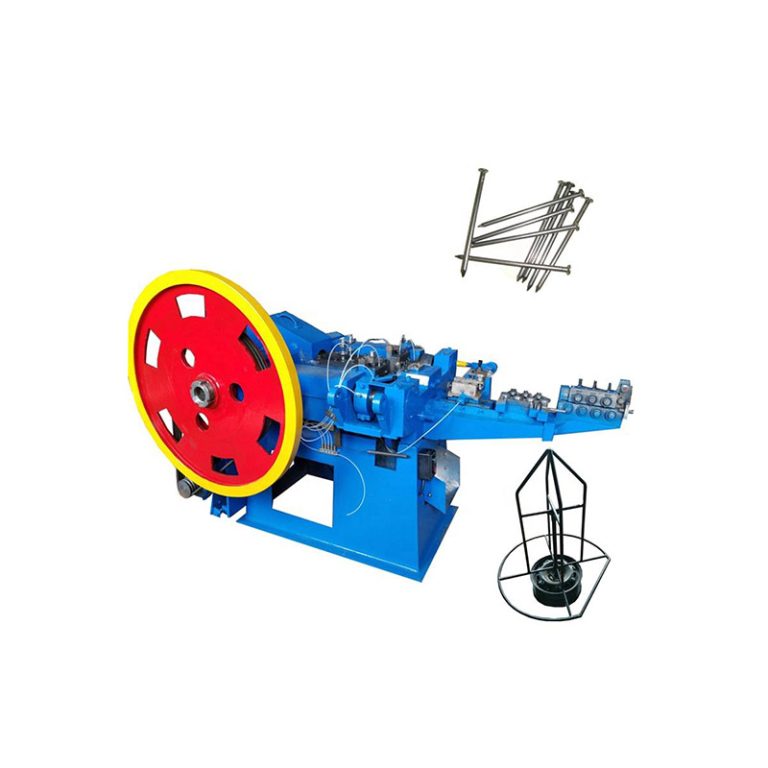

How to operate steel nail knife sharpening grinder machine

- Secure the machine on a stable surface and ensure it’s properly connected to a power source.

- Adjust the guide to the desired sharpening angle, which depends on the type of knife and its intended use. Common angles range from 15 to 30 degrees.

- Hold the knife firmly and place it against the guide. Turn on the machine and gently draw the knife across the grinding wheel. Maintain consistent pressure and angle to achieve an even edge.

- After sharpening, inspect the edge for consistency and sharpness. You may need to use a honing stone or strop to finish the edge and remove any burrs.