1-6 inch steel nail making machine is an industrial device used to manufacture steel nails from wire. These machines can vary in terms of automation, capacity, and complexity, and they are essential for producing nails used in construction, carpentry, and various other applications. Dingsheng steel nail making machine manufacturer can make the whole steel wire nail product line, such as nail polishing machine, nail grinder machine, steel wire drawing machine, butt-welding machine and roller tip machine. Our round steel nail making machine arrived in many countries like Bangladesh, Uzbekistan, India, Ukraine, Russia, Egypt and so on.

Main production process of 1-6 inch steel nail making machine

- Material: Original 6.5 mm in diameter Q195 & Q235 Carbon Steel

- Frequency Conversion Wire Drawing Machine: To draw the original 6.5 mm Carbon Steel to small diameter wire rod like 4.5 mm, 3.8 mm, 3.4 mm, 2.8 mm. The quick-wear parts are: Different size drawing mould, drawing powder.

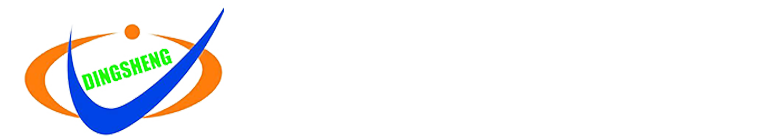

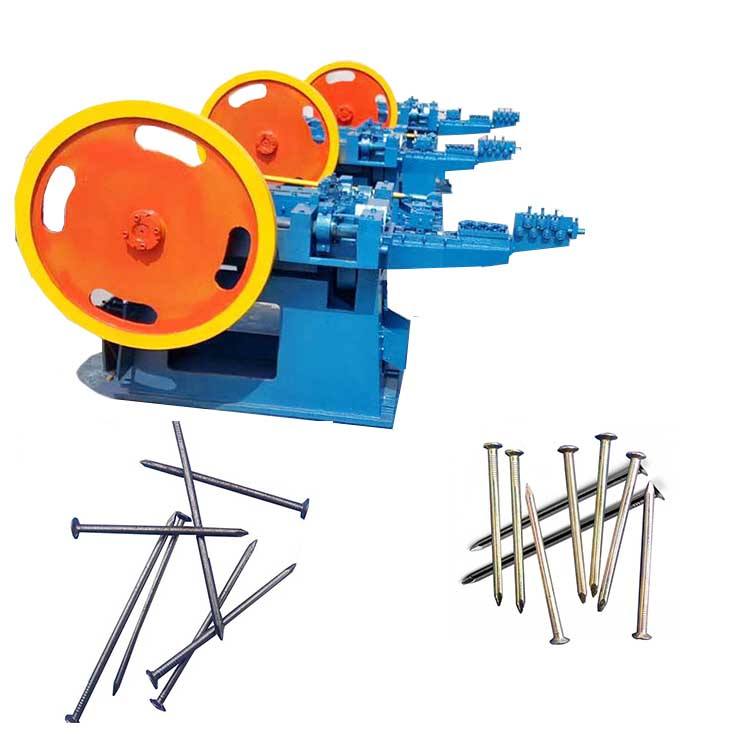

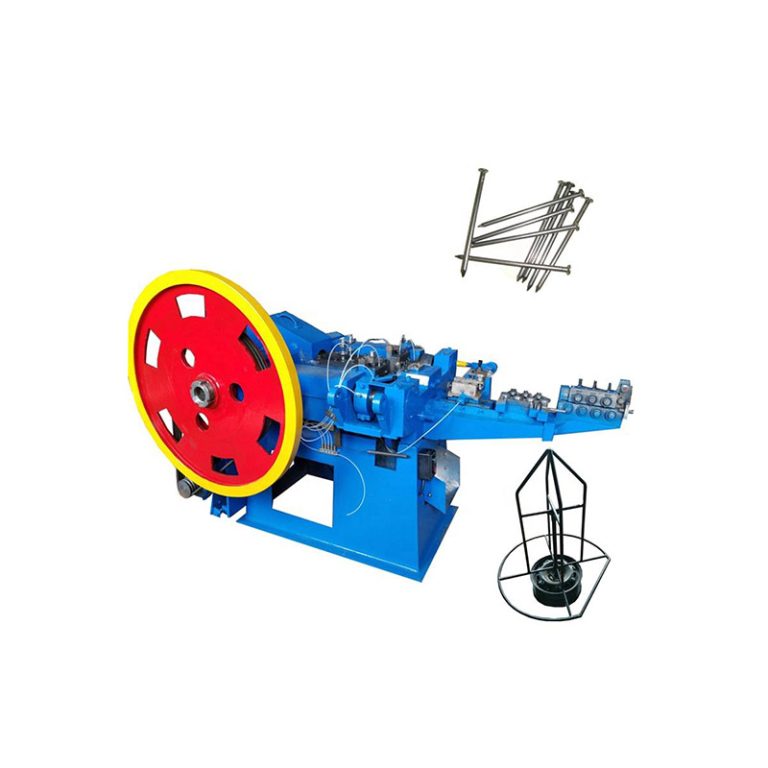

- Nail Making Machine: Put the small diameter coiled rod on a wire reel, then feeding it into the 1-6 inch steel nail making machine. Our Automatic steel nail making machine can form the Nail Head, Nail Shank, Nail Point with one time cutting. The quick-wear parts are: Nail Die Cutter, Nail Gripper Mould, Nail Punch Pin.

- Nail Polishing Machine: Put the semi-finished nails into the polishing drums, it will remove the dust iron of the semi-finished nail surfaces. The finished wire nails are bright and surfaces are very smooth.

- Nail Package: Generally, there are two ways for packing the common steel nails, they are Plastic Bag Packing and Paper Box Packing. This is mainly depending on the final customer’s requirements and buying habit.

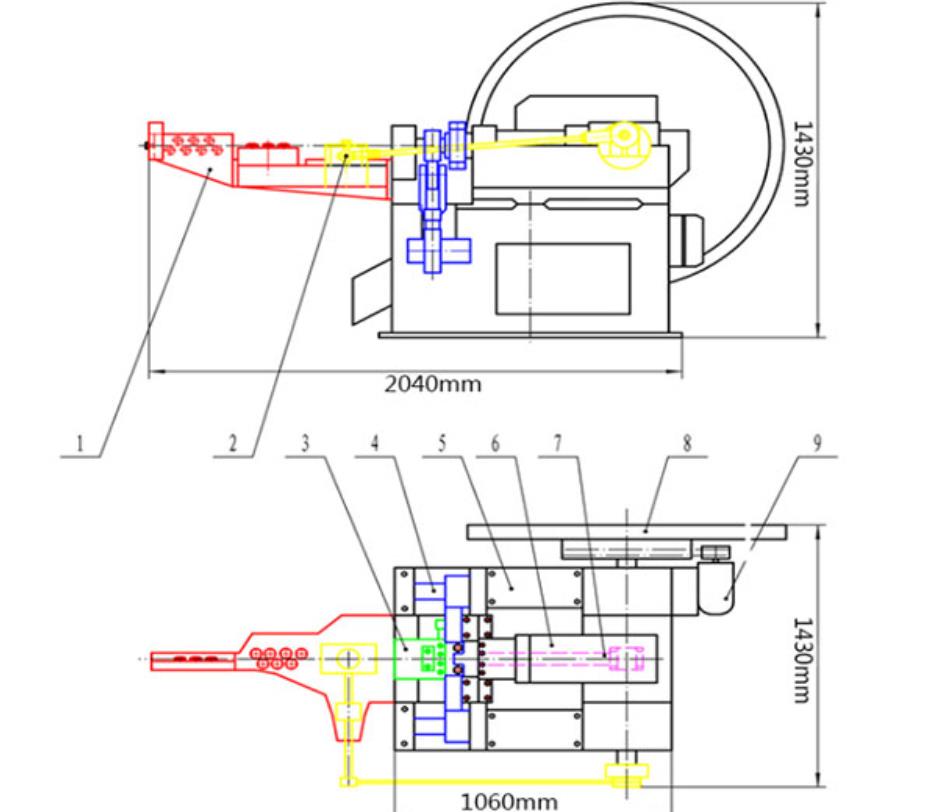

1-6 inch steel nail making machine structure:

The main structure of the nail-making machine, including the big wheel, mainframe, motor, discharge hopper, wire feeding mechanism, straightening mechanism, punching mechanism, mold mechanism, nail cutter cutting Mechanism, and gear transmission mechanism.

The features of 1-6 inch steel nail making machine

- This wire nail making machine adopts plunger type structure to ensure the high speed, low noise, less blunt acoustic.

- It has advanced design, compact structure, beautiful appearance, easy operation, safety and other features.

- Nails making machine is adopt of bearing and oil pipe lubricating structure to ensure the high working speed .

- Energy saving, stable and reliable performance. Quality up to standard, the device has small volume, flexible to move, low noise, low consumption, easy installation, etc.

- Product application: The common nails is widely used in construction and decoration, such as softand hard wood, bamboo ware, ordinary plastic, mud wall, repair furniture, packing wooden cases, etc.

How to choose correct models of 1-6 inch steel nail making machine?

Generally, the 1-4 Inch Nail Making Production Line and 1-6 Inch Steel Nail Making Machine are the popular choices for our clients. More than 90% foreign clients choose to manufacture the 1-4 Inch common steel nails or the 1-6 Inch common steel nails. Below are the proposals for setting the Basic Nail Making Factory:

1-4 Inch Nail Making Production Line:

Nail Making Machine Z94-2C

Nail Making Machine Z94-4C

Nail Polishing Machine with capacity 1000 kg

Nail Knife Grinding Machine

1-6 Inch Steel Nail Making Machine:

Nail Making Machine Z94-2C

Nail Making Machine Z94-4C

Nail Making Machine Z94-5C

Nail Polishing Machine with capacity 1000 kg

Nail Knife Grinding Machine